If you are worried about what happens to batteries of electric vehicles after their useful life, battery specialist has been working on how to make easy and economical to recycle batteries and has presented the result of their work.

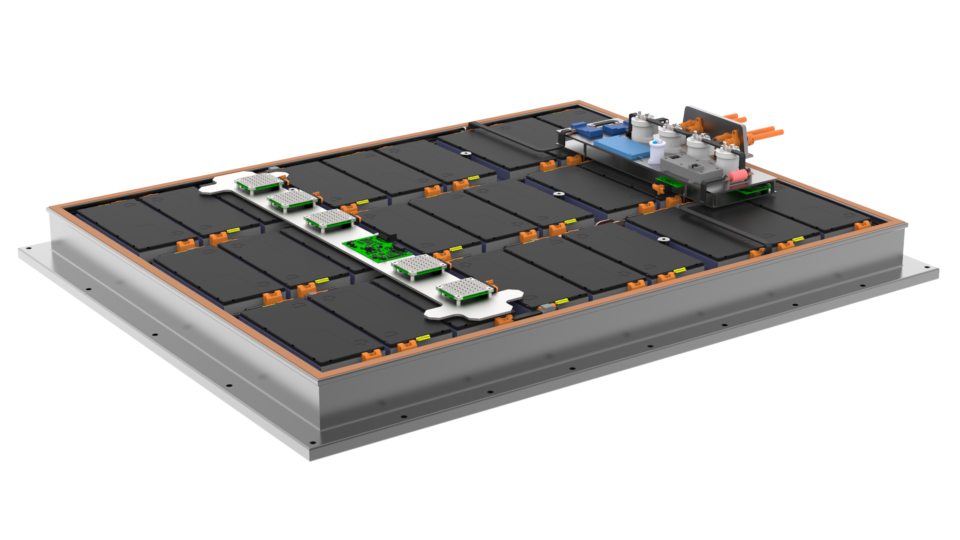

The batteries can be dismantled in a more resource-friendly way to reach the materials making them up and reuse them. To achieve this, Germany based IAV is using an entirely new battery pack and module concept which uses steel instead of aluminium as the former can be separated during the process of recycling using less energy. However, there is a tradeoff as the battery will weigh about 1 to 1.5 percent more, which is negligible.

IAV has also tried to cut down on the use of screws, gluing and welding in joining the battery components together, as they make it more difficult to dismantle the battery, the reason why many batteries are shredded with the result being loss of valuable materials.

In place of multiple screws, glues and welding, IAV have developed a joining system that use click and plug connection. While not eliminating screws completely, they have been reduced by two thirds, with the same going for gluing and welding.

As a result of this new design, battery recyclers can easily use robots to pull the batteries apart for recycling, saving both money and time. IAV sees 20 percent savings in CO2 emission over the lifetime of the battery. The cost of recycling will also be reduced by up to 50 percent.

IAV’s battery concept also complies with what could be a new European legislation on batteries, which proposes that there should be a gradual increase in recycling targets for some of the raw materials in lithium ion batteries by 2030.

To make it easy for vehicle manufacturers to switch to IAV’s new batteries, the company has made sure they are compatible with existing vehicle designs, retaining same dimensions and connections.

Michael Clauß, battery specialist at IAV says: “Thanks to the new design, recyclers can disassemble the battery system more easily and quickly. The design is such that robots can take over large parts of the work…The advantage for the customer is that the battery ends up with the same dimensions and connections as before, so it can be integrated into existing vehicle structures without any problems.”