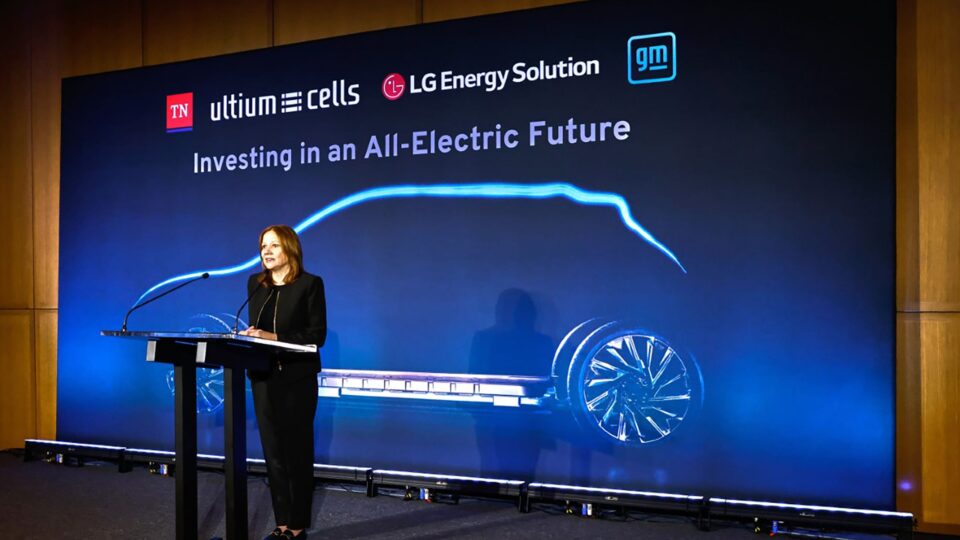

Electric vehicle battery production in the US is about to receive another boost as two heavyweights, General Motors and LG Energy Solution enter into an agreement to build another battery production plant in the US. The plant will cost $2.3 billion. The site selected for the project is in Spring Hill, Tennessee.

The agreement is a joint venture between the two companies and has been named Ultium Cells, a reference to the new battery-powered vehicle platform that GM is basing its electric models on.

The factory site is leased from GM. It will generate 1,300 direct employment when fully operational. Construction is expected to begin immediately.

This is coming after the joint-venture completed the construction of the first Ultium Cells battery facilities in Lordstown, Ohio. It will come online this quarter.

Production at Spring Hill will start in late 2023. It will build battery packs for the Cadillac Lyriq, an upcoming electric SUV from GM. The car will be produced in another plant in Spring Hill, thereby simplifying logistics. As the Lyriq is scheduled for release next year, the batches made before Spring Hill is ready will use power packs from another plant, although not from Lordstown.

The batteries from Spring Hill are going to use different materials and will be less expensive than those made at Lordstown. The former plant, which will cover 2.8 million square-foot, will be using advanced materials and production process. It is also designed to be flexible so as to accommodate any new battery tech and materials.

Mary Barra, GM CEO, commented; “The addition of our second all-new Ultium battery cell plant in the U.S. with our joint venture partner LG Energy Solution is another major step in our transition to an all-electric future. The support of the state of Tennessee was an important factor in making this investment in Spring Hill possible and this type of support will be critical moving forward.”

LG Energy Solution CEO, Jong Hyyun Kim had this to say: “I truly believe this coming together transcends a partnership as it marks a defining moment that will reduce emissions and help to accelerate the adoption of EVs.”

GM will need more battery making plants as it shifts to an electric vehicle only lineup by 2035. It has a more pressing deadline of releasing 30 new electric models by 2025, which will further test the automaker’s battery making capacity. The funds for the new battery plants will come from its $27 billion war chest.